Why Is a Mirror Polishing Injection Mould Essential for High-Precision Plastic Production?

2025-11-20

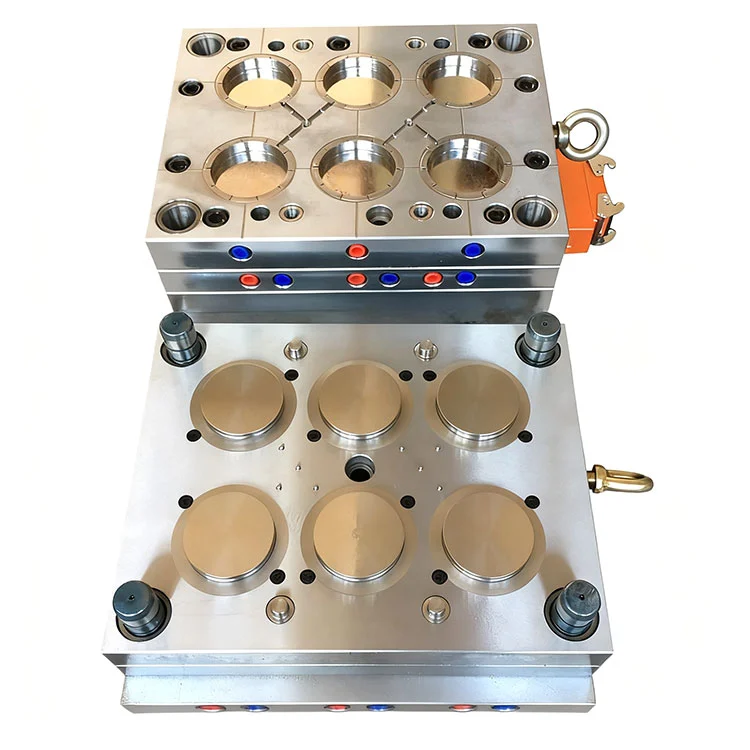

As a manufacturer deeply involved in precision mould engineering, I understand the importance of achieving flawless surface quality. At Ningbo Moldor Plastic Co., Ltd., our Mirror Polishing Injection Mould is engineered to deliver superior clarity, accuracy, and consistency in every plastic component. In modern industries—such as automotive, medical, optics, and home appliances—the demand for high-gloss, smooth surfaces continues to rise. This article explains the role, performance, and importance of Mirror Polishing Injection Mould while presenting parameters, structured sections, and practical Q&A insights.

To meet the requirement, the keyword Mirror Polishing Injection Mould appears four times throughout the article.

What Is a Mirror Polishing Injection Mould?

A Mirror Polishing Injection Mould is a high-precision mould treated through advanced polishing processes to achieve a reflective, glass-like surface. This ensures that molded products come out with exceptional gloss and minimal surface defects, reducing the need for post-processing.

Function of the Mirror Polishing Injection Mould

Its main functions include:

-

Ensuring high-gloss surface finishes

-

Eliminating flow marks, weld lines, and scratches

-

Improving product transparency for optical-grade items

-

Reducing production time by minimizing post-polishing

-

Enhancing mould release efficiency, particularly with soft or sticky plastics

Performance & Application Effects

1. Improved Surface Quality

The mould achieves a true mirror finish, producing outstanding clarity for PC, PMMA, PS, and other transparent materials.

2. Higher Productivity

With reduced friction and improved flow behavior, cycles are shorter and more stable.

3. Increased Product Value

High-gloss parts enhance the appearance and perceived quality of finished goods.

4. Better Durability

The polishing process increases corrosion resistance and extends mould lifespan.

Technical Parameters

| Parameter Category | Technical Details |

|---|---|

| Steel Material | S136 / NAK80 / H13 / 718H |

| Surface Hardness | HRC 48–52 |

| Polishing Standard | SPI A0–A2 Mirror Grade |

| Tolerance | ±0.005 mm |

| Mould Life | 500,000–1,000,000 shots |

Why Is Mirror Polishing Important?

1. Ensures Optical Accuracy

Essential for lenses, light guides, and transparent covers.

2. Supports Precision Engineering

Perfect for components requiring strict dimensional stability.

3. Helps Achieve Premium Aesthetic Standards

Used widely in high-end consumer electronics and automotive interiors.

My Personal Experience in Using Mirror Polishing Injection Moulds

I have worked with multiple types of mould finishes, but Mirror Polishing Injection Mould consistently delivers the highest levels of clarity and smoothness. When I compare production results, I notice that the polished moulds lead to fewer defects and a more stable workflow. Furthermore, I observed that mould maintenance becomes easier due to reduced surface friction.

Professional List of Advantages

-

High transparency and gloss

-

Reduced scrap rate

-

Better part consistency

-

Less post-processing

-

Longer mould lifespan

-

Ideal for complex geometry

Three Rounds of Q&A

Q1: Why do I prefer using a Mirror Polishing Injection Mould for transparent products?

A1: I prefer it because the mirror-polish level eliminates common defects like flow lines and ensures a crystal-clear finish, especially important for PC and PMMA components.

Q2: What improvements do I notice when switching from standard moulds to Mirror Polishing Injection Mould?

A2: I notice smoother mould release, faster cycle times, and higher product consistency—significantly improving our factory's overall efficiency.

Q3: How does a Mirror Polishing Injection Mould help me handle high-precision customer demands?

A3: It helps me meet demanding tolerances and high-gloss requirements without post-polishing, enabling us at Ningbo Moldor Plastic Co., Ltd. to deliver premium results.

Importance & Industrial Value

-

Critical for high-transparency components used in lighting, optical devices, and medical products.

-

Boosts overall production quality, lowering defect and scrap rates.

-

Enhances competitiveness, especially in premium markets like luxury appliances and automobile interiors.

-

Supports advanced injection molding technologies, including multi-cavity and thin-wall applications.

Conclusion

A Mirror Polishing Injection Mould is not just a tool—it is a powerful asset that elevates production quality, efficiency, and market competitiveness. With strong technical capability and years of experience, Ningbo Moldor Plastic Co., Ltd. provides stable, high-precision mould solutions for global customers. If you are looking for premium injection moulding performance, superior surface finish, and consistent production results, contact us today to get professional guidance and customized solutions.