What Makes Diamond Milling Cutters the Future of Precision Machining?

2025-11-06

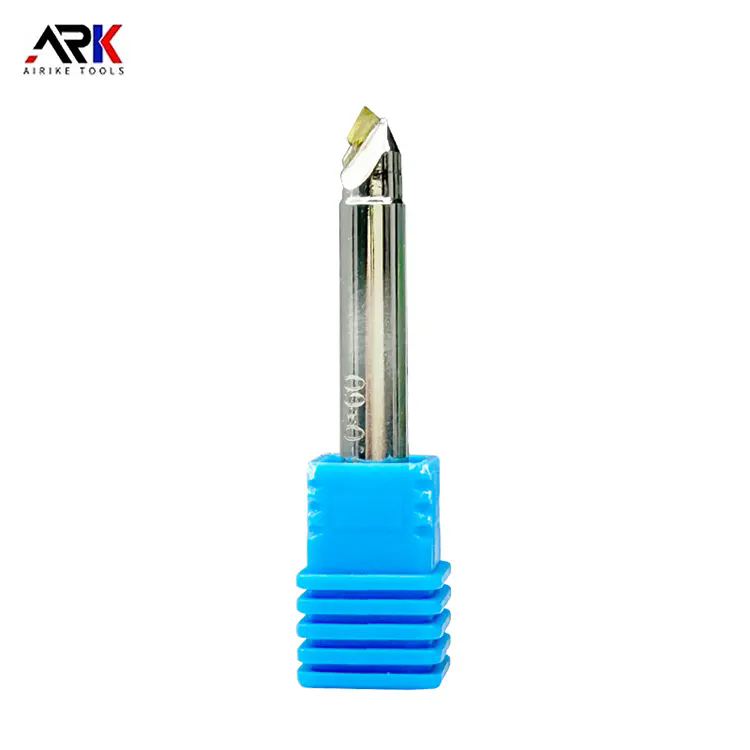

Diamond Milling Cutters represent a major advancement in the field of precision machining, providing exceptional hardness, durability, and cutting efficiency unmatched by conventional carbide or ceramic tools. These cutters are typically equipped with polycrystalline diamond (PCD) or chemical vapor deposition (CVD) diamond coatings, which deliver superior wear resistance and high-speed cutting capabilities. The combination of synthetic diamond materials and precision engineering enables them to handle challenging materials such as aluminum alloys, composites, ceramics, carbon fiber, and graphite with remarkable precision.

What Are the Key Features and Specifications of Diamond Milling Cutters?

Diamond Milling Cutters are designed with highly engineered geometries and ultra-hard materials that significantly improve machining outcomes. Below is a detailed table summarizing the common parameters and specifications typically associated with high-performance diamond milling tools:

| Parameter | Description |

|---|---|

| Material Composition | Polycrystalline Diamond (PCD), Monocrystalline Diamond (MCD), or CVD Diamond |

| Cutting Edge Hardness | 8,000 – 10,000 HV (Vickers Hardness) |

| Grain Size | 2 µm to 25 µm depending on application |

| Helix Angle | 15°–30° for smooth chip evacuation |

| Tool Diameter Range | 0.2 mm – 20 mm |

| Shank Material | Tungsten Carbide or Solid Carbide |

| Coating Type | Diamond Coating (CVD, DLC, or PCD tips) |

| Cutting Speed (Vc) | Up to 3,000 m/min depending on work material |

| Feed Rate (Fz) | 0.02 – 0.2 mm/tooth depending on cutter size |

| Surface Roughness (Ra) | Up to 0.1 µm achievable on non-ferrous materials |

| Tool Life | Up to 50 times longer than conventional carbide tools |

The above parameters demonstrate how Diamond Milling Cutters combine ultra-hard materials with precise engineering to ensure stable, repeatable, and high-quality performance during continuous production.

Why Are Diamond Milling Cutters Important for Modern Manufacturing?

The reason Diamond Milling Cutters have become increasingly significant lies in their ability to address three key industrial challenges — efficiency, durability, and precision. These tools are engineered to maximize cutting life while minimizing downtime and material waste.

a. Exceptional Hardness and Wear Resistance

Diamond, being the hardest known material, provides unmatched wear resistance. This allows manufacturers to achieve longer tool life even under high-speed or high-temperature conditions. In industries like aerospace, where titanium and composite materials are commonly used, this feature drastically reduces tool changes and enhances process stability.

b. Superior Surface Finish and Dimensional Accuracy

Due to the extreme sharpness and stability of the diamond cutting edge, these tools deliver mirror-like finishes and extremely tight dimensional tolerances. This is critical for producing molds, optical components, and precision parts that require flawless surfaces.

c. Energy and Cost Efficiency

Diamond Milling Cutters minimize friction and cutting force, reducing spindle load and energy consumption. This leads to lower operational costs and extended equipment lifespan. When evaluated in total cost of ownership, diamond tools often outperform conventional carbide tools by more than 400% in terms of productivity.

d. Ideal for Non-Ferrous and Composite Materials

While diamond tools are not suitable for machining ferrous metals due to chemical affinity between carbon and iron, they are perfect for cutting materials like aluminum, graphite, carbon fiber, copper, and reinforced plastics. These materials are common in advanced manufacturing sectors where lightweight and precision are paramount.

How Do Diamond Milling Cutters Work and Improve Machining Efficiency?

The operation of Diamond Milling Cutters is rooted in precision geometry and advanced coating technology. Their unique cutting mechanisms ensure consistent performance across a wide range of speeds and materials.

a. Cutting Mechanism

The diamond cutting edge shears the material instead of plowing through it, resulting in minimal deformation and heat generation. This allows for ultra-fine chip removal and superior surface quality.

b. Heat Dissipation

Diamond materials have high thermal conductivity, enabling rapid heat transfer away from the cutting zone. This reduces tool wear and prevents thermal damage to workpieces, especially during high-speed milling operations.

c. Enhanced Tool Geometry

Optimized rake and clearance angles, coupled with specific helix designs, ensure smooth chip evacuation. This helps prevent chip adhesion and material buildup on the cutting edge, maintaining sharpness and accuracy over prolonged use.

d. Application-Specific Engineering

Manufacturers can customize diamond milling cutters according to their specific applications — for example, fine-grain diamond edges for high-precision finishing or coarse-grain diamond tips for roughing hard composites. This adaptability makes them versatile across diverse industries.

What Are the Future Trends in Diamond Milling Cutter Technology?

The global machining industry is moving rapidly toward automation, sustainability, and precision-driven innovation. Diamond Milling Cutters are expected to play a crucial role in this transformation. Below are the emerging trends that define their future trajectory:

a. Nanocrystalline Diamond Coatings

New generations of nanocrystalline diamond coatings are being developed to offer even higher hardness and smoother surfaces. These coatings significantly enhance cutting speed, reduce friction, and extend tool lifespan beyond what was previously possible.

b. Integration with Smart Machining Systems

As smart manufacturing and Industry 4.0 become standard, diamond tools will increasingly integrate with digital machining platforms. Real-time data from sensors embedded in CNC systems will help monitor wear patterns and predict tool life accurately.

c. Environmentally Sustainable Machining

With reduced friction and longer tool life, diamond cutters contribute to sustainable production by minimizing waste and lowering energy consumption. This aligns with global trends toward eco-efficient manufacturing.

d. 3D Printing and Additive Manufacturing Compatibility

Future developments may see diamond cutters optimized for post-processing 3D-printed components. Their precision makes them ideal for fine-tuning complex geometries that additive manufacturing often produces.

Frequently Asked Questions About Diamond Milling Cutters

Q1: What materials should not be machined with Diamond Milling Cutters?

A1: Diamond Milling Cutters are not recommended for ferrous materials such as steel, cast iron, or stainless steel. When machining these materials, the carbon atoms in diamond react chemically with iron at high temperatures, causing rapid wear or degradation of the tool edge. These cutters are best suited for non-ferrous materials such as aluminum alloys, copper, brass, composites, and ceramics.

Q2: How can the lifespan of a Diamond Milling Cutter be extended?

A2: The longevity of a diamond cutter depends on proper cutting parameters, cooling techniques, and material compatibility. Using optimal spindle speeds, maintaining adequate coolant flow, and avoiding aggressive feeds all contribute to prolonged tool life. Additionally, regular inspection and cleaning of the cutting edge prevent buildup that can cause premature wear. When stored correctly in dry, clean environments, diamond tools can retain their performance characteristics for extended periods.

The Precision Future with Zhongye Da Diamond Milling Cutters

Diamond Milling Cutters have redefined what is achievable in precision machining. From ultra-smooth finishes to dramatically extended tool life, they provide manufacturers with measurable advantages in efficiency and quality. As industries shift toward automation and sustainability, these tools are set to become an essential part of high-performance production systems.

Zhongye Da, a leading name in advanced cutting tool solutions, continues to push the boundaries of diamond tooling innovation. With a focus on reliability, precision, and customer-centered design, Zhongye Da delivers products engineered for superior performance and consistency across demanding applications.

For more information about our range of Diamond Milling Cutters or to discuss your specific machining needs, contact us today to discover how Zhongye Da can elevate your production capabilities and help you achieve the next level of precision manufacturing.