How Does the Maze Cage-Guide Control Valve Improve Industrial Flow Efficiency?

2025-10-15

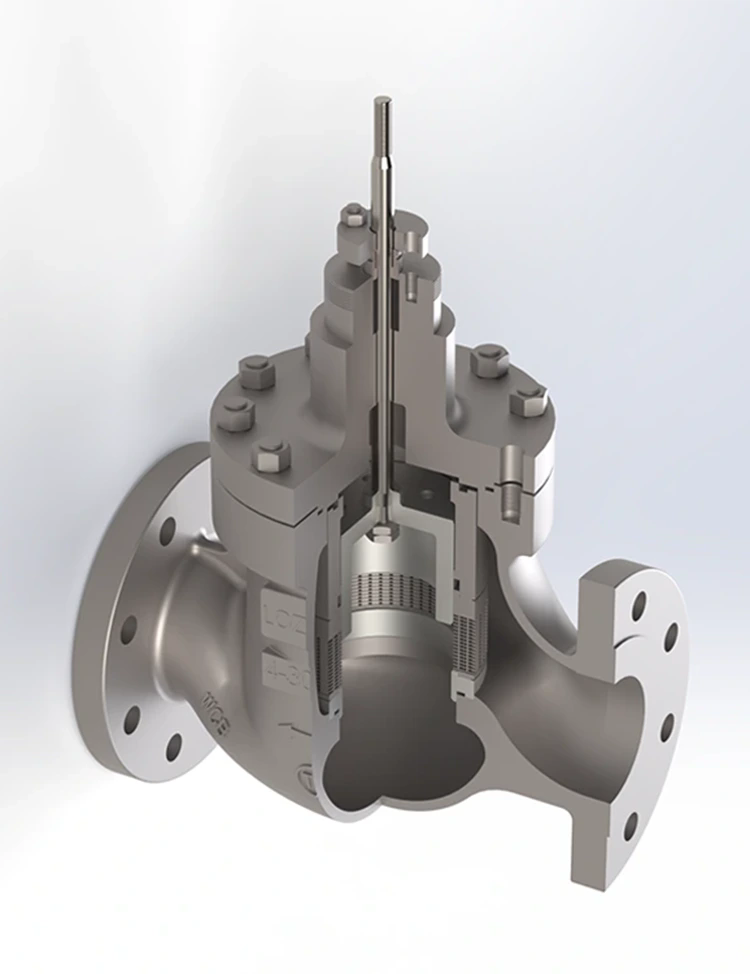

The Maze Cage-Guide Control Valve is a cutting-edge solution designed to provide precise control over fluid flow in industrial systems. Combining advanced engineering with robust materials, this valve addresses common challenges in flow regulation, such as erosion, noise, cavitation, and pressure drop. Its innovative cage-guide design ensures superior stability, extended service life, and minimal maintenance requirements.

What is the Maze Cage-Guide Control Valve and Why is it Important?

The Maze Cage-Guide Control Valve is a type of globe valve that incorporates a specially designed cage surrounding the valve plug. This design allows for controlled flow passage, reducing turbulence and ensuring even distribution of pressure across the valve. By minimizing vibration and noise, it enhances operational reliability, especially in critical industrial environments such as chemical plants, power generation, and oil & gas pipelines.

Key Benefits of the Maze Cage-Guide Control Valve:

-

Enhanced flow stability and accuracy

-

Reduced noise and vibration for safer operations

-

Increased resistance to cavitation and erosion

-

Longer lifespan with lower maintenance costs

-

Compatible with high-pressure and high-temperature applications

Technical Specifications:

| Parameter | Specification |

|---|---|

| Valve Type | Globe, Cage-Guide |

| Nominal Diameter (DN) | 15mm – 500mm |

| Pressure Rating (PN/ANSI) | PN16 – PN250 / Class 150 – Class 600 |

| Temperature Range | -196°C to 550°C |

| Flow Coefficient (Cv) | 0.5 – 4200 |

| Materials of Construction | Stainless Steel, Carbon Steel, Alloy Steel Options |

| Connection Type | Flanged, Butt Welded, Threaded |

| Actuation | Pneumatic, Electric, Hydraulic |

| Trim Options | Anti-cavitation, Noise-Reducing, High-Pressure |

The valve’s structure allows it to maintain high performance even under challenging operating conditions. Its precision-engineered cage guides the plug, reducing throttling-induced wear and ensuring consistent control across various flow rates.

How Does the Maze Cage-Guide Control Valve Work?

The working principle of the Maze Cage-Guide Control Valve revolves around the interaction between the cage, plug, and flow stream. As fluid enters the valve, it passes through the perforated cage structure. The cage distributes the flow evenly around the plug, minimizing turbulence and preventing uneven wear. The plug’s movement, controlled by an actuator, regulates the flow rate with high precision.

Step-by-Step Operation:

-

Flow Entry: Fluid enters through the valve inlet.

-

Flow Regulation: The plug moves along the guided cage, reducing or increasing the flow area as needed.

-

Pressure Management: The cage ensures pressure drop is controlled, reducing the risk of cavitation.

-

Flow Exit: Fluid exits with stable flow and minimized noise or vibration.

The valve’s ability to handle high-pressure drops while maintaining accurate control makes it ideal for systems where safety and efficiency are critical. Its modular trim options allow customization for specific industrial requirements, such as anti-cavitation trim for high-pressure steam applications or noise-reduction trim for sensitive operations.

Why Choose Maze Cage-Guide Control Valves Over Conventional Valves?

Conventional globe or butterfly valves often struggle with high turbulence, erosion, and noise in demanding environments. The Maze Cage-Guide design:

-

Ensures smoother flow transitions and reduced energy losses

-

Protects critical components from cavitation and erosion

-

Offers precise flow control even in variable process conditions

-

Requires less frequent maintenance, reducing operational costs

By integrating these advanced features, the Maze Cage-Guide Control Valve provides both operational efficiency and long-term cost savings.

Why Are Maze Cage-Guide Control Valves Essential for Modern Industrial Applications?

Industries today face increasingly stringent requirements for energy efficiency, safety, and environmental compliance. The Maze Cage-Guide Control Valve meets these challenges with unmatched reliability and performance.

Key Industrial Applications:

-

Power Plants: Precise steam flow regulation, noise reduction, and cavitation resistance.

-

Petrochemical & Oil & Gas: Handling corrosive fluids and high-pressure drops without compromising safety.

-

Chemical Processing: Accurate dosing and flow stability for complex chemical reactions.

-

Water Treatment & HVAC Systems: Reliable control of water or other fluids in large-scale facilities.

Common Advantages in Industrial Settings:

-

Noise Control: The perforated cage reduces sound levels caused by turbulent flow, improving worker safety.

-

Cavitation Resistance: High-pressure systems benefit from anti-cavitation trim, reducing component wear.

-

Durability: High-quality materials and cage-guided plug design significantly extend service life.

-

Flexibility: Suitable for a wide range of fluids, temperatures, and pressures.

Frequently Asked Questions:

Q1: What maintenance does the Maze Cage-Guide Control Valve require?

A1: Maintenance is minimal due to the cage-guided plug design, which reduces wear. Regular inspection involves checking actuator function, seal integrity, and verifying trim condition every 12–24 months, depending on operating conditions.

Q2: Can the valve handle corrosive or high-temperature fluids?

A2: Yes. The valve is available in stainless steel and alloy steel options with suitable trim materials, allowing safe operation with corrosive fluids or temperatures up to 550°C. Special coatings can further enhance resistance to aggressive chemical environments.

How Will Maze Cage-Guide Control Valves Shape Future Industrial Flow Control Trends?

The evolution of industrial flow control is moving toward precision, durability, and energy efficiency. Maze Cage-Guide Control Valves play a pivotal role in this shift by offering:

-

Advanced Flow Control: Digital and smart actuator options allow real-time monitoring and adjustment for maximum efficiency.

-

Sustainability: Reduced energy loss and longer valve lifespan contribute to lower carbon footprints.

-

Integration: Compatible with modern industrial automation systems for predictive maintenance and remote operation.

-

Global Standards Compliance: Designed to meet ANSI, API, and ISO standards, ensuring wide applicability across industries worldwide.

As industrial facilities demand safer, more efficient, and environmentally responsible operations, the Maze Cage-Guide Control Valve stands out as a reliable choice.

LOZOSE specializes in providing high-performance Maze Cage-Guide Control Valves tailored to diverse industrial needs. With a commitment to quality, precision engineering, and customer satisfaction, LOZOSE ensures that every valve delivers optimal performance over its lifespan. For inquiries about specific models, technical support, or project consultation, contact us to discover how Maze Cage-Guide Control Valves can elevate your industrial operations.