How Does Peripheral Diamond Grinding Improve Precision and Efficiency in Modern Manufacturing?

2025-12-02

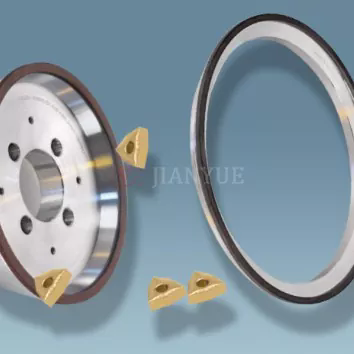

Peripheral diamond grinding has emerged as a cornerstone technology in precision machining, offering unmatched accuracy, surface finish, and efficiency for a wide range of industrial applications. By utilizing the superior hardness and wear resistance of diamond abrasives, this method ensures consistent quality even when machining the hardest materials.

What Are the Key Advantages of Peripheral Diamond Grinding?

Peripheral diamond grinding stands out for several reasons that make it essential in high-precision industries. These advantages include enhanced surface quality, extended tool life, faster processing times, and adaptability to various materials.

-

High Precision Machining: Peripheral diamond grinding delivers tight tolerances, often achieving surface finishes below Ra0.2 μm, which is critical for optical components, aerospace parts, and automotive precision elements.

-

Durability and Longevity: The use of industrial-grade diamond grains minimizes wear, allowing for extended operational life and reduced downtime for tool replacement.

-

Versatility: Suitable for metals, ceramics, carbides, and composite materials, peripheral diamond grinding offers broad compatibility across diverse manufacturing sectors.

-

Efficiency: Optimized peripheral grinding reduces cycle times by up to 40% compared to traditional grinding methods, enhancing overall production throughput.

-

Reduced Thermal Damage: Diamond abrasives dissipate heat more effectively, preventing micro-cracks and thermal stress on sensitive components.

These benefits make peripheral diamond grinding an indispensable choice in applications requiring both precision and productivity.

What Are the Core Technical Specifications of Peripheral Diamond Grinding Tools?

Understanding the specifications of peripheral diamond grinding tools is essential to selecting the right product for specific machining tasks. Below is a comprehensive table summarizing key parameters:

| Parameter | Specification | Description |

|---|---|---|

| Bond Type | Resin, Metal, Electroplated | Determines grinding behavior, wear resistance, and surface finish |

| Diamond Grit Size | 80# – 3000# | Controls material removal rate and surface finish quality |

| Wheel Diameter | 50 mm – 500 mm | Suitable for both small precision components and large industrial parts |

| Wheel Width | 5 mm – 50 mm | Influences grinding depth and stability |

| Max RPM | 3,000 – 15,000 | Ensures high-speed operation while maintaining safety |

| Application Material | Carbide, Ceramic, Hardened Steel, Glass | Covers a wide spectrum of industrial materials |

| Wheel Shape | Straight, Tapered, Segmented | Adaptable for various contouring and peripheral grinding tasks |

| Surface Finish | Ra0.1 – Ra0.5 μm | Achieves ultra-smooth surfaces for optical and mechanical components |

These specifications ensure that engineers can match the peripheral diamond grinding tool to their production needs, optimizing both performance and cost efficiency.

How Does Peripheral Diamond Grinding Enhance Manufacturing Processes?

Peripheral diamond grinding improves manufacturing processes through precision control, operational efficiency, and adaptability across industries. It answers the demand for tighter tolerances and superior surface quality in high-tech sectors.

1. Precision and Accuracy

Peripheral grinding uses the edge of the diamond wheel to remove material with micrometer-level accuracy. This is particularly important in applications such as aerospace turbine blades, automotive transmission components, and semiconductor wafers, where even minor deviations can compromise functionality. Advanced CNC-controlled grinding machines further enhance precision by controlling feed rates, wheel speed, and depth of cut.

2. Surface Finish Quality

The diamond abrasive's hardness ensures that peripheral grinding produces an extremely fine surface finish without generating burrs. This is crucial for optical lenses, medical devices, and tooling components. Achieving a smooth surface reduces the need for secondary finishing processes, saving both time and costs.

3. Material Versatility

From hardened steel to brittle ceramics, peripheral diamond grinding adapts to materials with different hardness and structural characteristics. This versatility allows manufacturers to consolidate multiple machining steps into a single, efficient grinding operation.

4. Heat Reduction and Tool Longevity

Compared to conventional grinding, diamond abrasives reduce frictional heat during machining. Lower heat generation prevents thermal damage, micro-cracks, and surface discoloration. Additionally, the durability of diamond ensures prolonged tool life, reducing replacement frequency and production interruptions.

5. Process Optimization and Cost Efficiency

By shortening cycle times and reducing the need for secondary processing, peripheral diamond grinding contributes directly to manufacturing cost savings. High-speed grinding wheels, combined with precise machine control, maximize material removal without sacrificing accuracy or surface quality.

What Are Common Applications of Peripheral Diamond Grinding?

Peripheral diamond grinding has become standard in industries requiring high precision, durability, and efficiency. Key applications include:

-

Aerospace Industry: Turbine blades, bearings, and high-strength metal components.

-

Automotive Industry: Engine components, gears, and transmission elements.

-

Electronics and Semiconductor Manufacturing: Silicon wafers, ceramic substrates, and conductive materials.

-

Medical Devices: Surgical tools, orthopedic implants, and dental equipment.

-

Optical Components: Lenses, mirrors, and precision glass elements.

In each sector, the combination of precision, surface finish, and material adaptability makes peripheral diamond grinding a preferred solution over traditional grinding methods.

Frequently Asked Questions About Peripheral Diamond Grinding

Q1: How do I choose the right diamond grit size for my application?

A1: The grit size should match the desired surface finish and material hardness. Coarser grits (80#–220#) are used for rough material removal, while finer grits (600#–3000#) are suitable for polishing and achieving ultra-smooth surfaces. Selection also depends on the feed rate, wheel speed, and machine capabilities.

Q2: Can peripheral diamond grinding be used on brittle materials without causing cracks?

A2: Yes. Peripheral diamond grinding generates less heat and applies precise material removal, which minimizes stress on brittle materials. Choosing the correct wheel bond and adjusting feed rates are critical to preventing micro-cracks or chipping during grinding.

What Are the Emerging Trends and Future Prospects in Peripheral Diamond Grinding?

Peripheral diamond grinding continues to evolve, driven by technological advancements and the growing demand for precision manufacturing.

1. Automation and CNC Integration

Integration with CNC systems allows for fully automated grinding operations, reducing human error and ensuring repeatable accuracy. Advanced sensors and real-time monitoring further enhance process control, enabling adaptive grinding strategies based on material behavior.

2. High-Efficiency Diamond Wheels

Newly engineered diamond wheels with optimized bonding and advanced grit distribution improve material removal rates while maintaining surface quality. These wheels can handle complex geometries and reduce cycle times, boosting overall productivity.

3. Hybrid Material Machining

The demand for composite materials in aerospace, electronics, and automotive industries drives the need for diamond grinding solutions that can handle multiple materials simultaneously without tool wear or performance loss.

4. Sustainability and Cost Reduction

Longer tool life, reduced energy consumption, and minimized waste make peripheral diamond grinding an environmentally friendly and cost-effective choice. Manufacturers increasingly prioritize sustainable production methods without compromising precision.

Peripheral diamond grinding represents a convergence of precision, durability, and efficiency. With continuous improvements in wheel design, automation, and material compatibility, its applications will expand further across high-tech manufacturing sectors. For businesses looking to adopt cutting-edge grinding solutions, JIANYUE offers a comprehensive range of peripheral diamond grinding tools engineered for maximum precision and reliability.

Contact us to explore product specifications, technical support, and customized grinding solutions tailored to your manufacturing requirements.