How Does a Cryogenic Control Valve Ensure Stable Flow at Extremely Low Temperatures?

2026-01-07

Article Abstract

How can industrial flow systems remain safe, precise, and reliable at temperatures approaching absolute zero? Cryogenic control valves are engineered to regulate fluids such as liquefied natural gas, liquid nitrogen, liquid oxygen, and liquid hydrogen under extreme thermal conditions. This article provides a comprehensive technical overview of cryogenic control valves, focusing on operating principles, structural design, key parameters, real-world applications, and frequently asked questions. The content is structured to support engineering decision-making, procurement evaluation, and long-term system planning while aligning with global search behavior and professional reading habits.

Table of Contents

- How Is a Cryogenic Control Valve Designed for Ultra-Low Temperature Conditions?

- How Do Technical Parameters Define Cryogenic Control Valve Performance?

- How Are Cryogenic Control Valves Applied Across Industries?

- How Can Common Questions About Cryogenic Control Valves Be Answered Clearly?

How Is a Cryogenic Control Valve Designed for Ultra-Low Temperature Conditions?

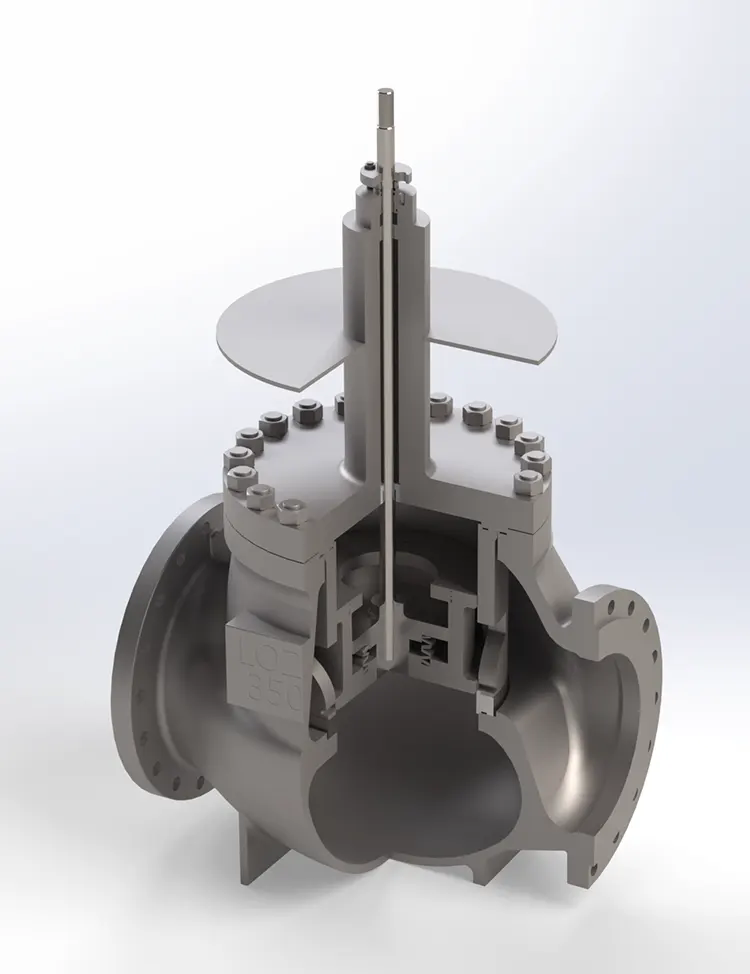

A cryogenic control valve is a precision-engineered flow regulation device specifically developed to operate at temperatures typically below -40°C and often reaching as low as -196°C. Unlike conventional control valves, cryogenic variants must maintain sealing integrity, structural stability, and control accuracy despite extreme thermal contraction and material embrittlement risks.

The core design philosophy centers on thermal isolation and controlled heat ingress. Extended bonnet structures are commonly used to separate the packing and actuator from cryogenic fluids, preventing freezing or loss of elasticity in sealing components. Internal flow paths are optimized to reduce turbulence, minimize flashing, and control phase change phenomena.

Material selection is another critical design dimension. Austenitic stainless steels, aluminum alloys, and specialized nickel-based alloys are frequently employed due to their excellent toughness at cryogenic temperatures. Soft sealing materials are replaced with engineered polymers or metal-to-metal sealing solutions capable of withstanding repeated thermal cycling.

How Do Technical Parameters Define Cryogenic Control Valve Performance?

Evaluating a cryogenic control valve requires careful analysis of its technical parameters. These parameters directly influence operational stability, control precision, and lifecycle reliability within cryogenic systems.

| Parameter | Typical Range | Engineering Significance |

|---|---|---|

| Design Temperature | -40°C to -196°C | Defines suitability for LNG, LN₂, LOX, and LH₂ applications |

| Pressure Rating | ANSI Class 150–2500 | Determines safe operation under high-pressure cryogenic storage |

| Body Material | SS304, SS316, Monel | Ensures toughness and corrosion resistance at low temperatures |

| Flow Characteristic | Equal %, Linear | Affects control accuracy during throttling |

| Bonnet Type | Extended bonnet | Protects packing from freezing and leakage |

Each parameter must be matched to process conditions such as fluid type, inlet pressure, temperature gradient, and required response time. Improper parameter alignment can result in seat leakage, unstable control loops, or premature valve failure.

How Are Cryogenic Control Valves Applied Across Industries?

Cryogenic control valves serve as critical components in multiple industrial sectors where ultra-low-temperature fluids are stored, transported, or processed. Their application scope continues to expand alongside the growth of clean energy and advanced manufacturing.

In liquefied natural gas facilities, cryogenic control valves regulate flow during liquefaction, storage tank management, and regasification processes. In industrial gas production, these valves maintain precise control of liquid oxygen and nitrogen used in steelmaking, electronics manufacturing, and medical systems.

Aerospace and hydrogen energy sectors also rely heavily on cryogenic control valves. Liquid hydrogen fueling systems demand extremely tight shutoff performance and rapid response capabilities, while space launch infrastructure requires valves that can withstand repeated thermal shocks without degradation.

Across these applications, the common requirement is predictable, repeatable control under conditions that would rapidly degrade standard valve assemblies.

How Can Common Questions About Cryogenic Control Valves Be Answered Clearly?

Q: How does a cryogenic control valve prevent leakage at extremely low temperatures?

A: Leakage prevention is achieved through extended bonnet designs, low-temperature-compatible packing materials, and precision-machined seats that compensate for thermal contraction while maintaining contact pressure.

Q: How is flow stability maintained when cryogenic fluids change phase?

A: Flow stability is maintained by optimized trim design that minimizes cavitation, flashing, and two-phase flow effects, combined with accurate actuator control and proper sizing calculations.

Q: How often should a cryogenic control valve be inspected or maintained?

A: Inspection intervals depend on operating cycles and media type, but periodic checks of packing integrity, actuator response, and seat wear are essential to ensure long-term reliability.

How Will Cryogenic Control Valve Technology Continue to Evolve?

As global energy systems shift toward liquefied gases and hydrogen-based infrastructure, cryogenic control valve technology is expected to advance in areas such as smart diagnostics, predictive maintenance integration, and enhanced materials science. Digital positioners and sensor-enabled valves are increasingly deployed to improve process transparency and operational efficiency.

Manufacturers are also investing in advanced testing protocols, including thermal shock testing and extended lifecycle simulations, to ensure valves can meet the demands of next-generation cryogenic systems.

Conclusion and Industry Perspective

Cryogenic control valves are indispensable to modern industrial systems that operate at ultra-low temperatures. Their specialized design, precise parameterization, and proven performance across multiple industries make them a foundational component in LNG, industrial gas, aerospace, and clean energy applications.

Within this evolving landscape, LOZOSE continues to focus on engineered cryogenic control valve solutions that align with stringent international standards and real-world operating conditions. By emphasizing reliability, precision, and application-specific design, LOZOSE supports customers seeking long-term operational stability in demanding cryogenic environments.

For detailed technical consultation, application matching, or customized cryogenic control valve solutions, contact us to engage with a professional engineering team dedicated to supporting complex low-temperature flow control requirements.